Tool Die Steels A-2, A.2, Applied to the thermosetting plastic mold, the hardened mould as a whole

A-2 Tool Die Steels Properties Data

Chemical Composition of steel A-2 Tool Die Steels: ,Cross Reference

A-2 Tool Die Steels Applications and Specifications

ADVANTAGES:

Good combination of wear resistance and toughness. Very stable in heat treatment.

Not difficult to machine or grind.

Good Hardenability.

AVAILABILITY

Readily available

MACHINABILITY

A-2 can be machined readily in the fully annealed condition. Its machinability rating is about 65% of a 1% carbon tool steel. It also has a high grindability rating.

ANNEALING

Heat slowly to 1500 to 1600°F and furnace cool, allowing the temperature to drop about 75°Fper hour to 1000°F. Then air cool. The annealed hardness is 202 to 248 Brinell.

HARDENING

A-2 should be preheated at 1200° to 1300°F then taken up to 1725° to 1750°F. When part is at temperature it should be soaked 30 minutes for the first inch of thickness and 15 minutes for each inch of thickness over one inch. If a controlled atmosphere or vacuum furnace is not available then part should be wrapped in stainless foil to prevent decarburization. When the piece is taken from the furnace the stainless foil must be removed (if applicable) and then cooled in still air. Large pieces may require forced air.

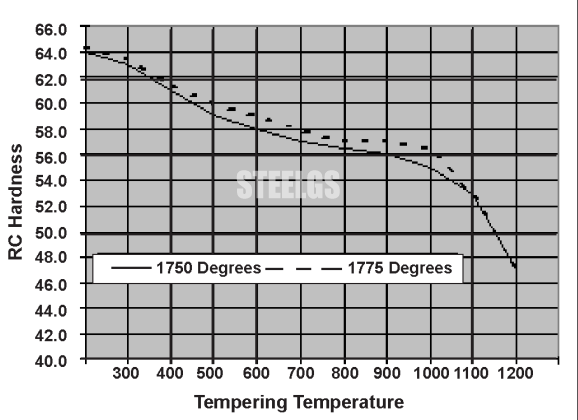

TEMPERING

As soon as pieces have been cooled to room temperature (100° to 125°F) tempering must begin. Heat slowly to the tempering temperature selected to obtain the hardness desired. Double tempering is recommended.

Mechanical properties at room temperature for A-2 Tool Die Steels:

Tensile Strength,Rm(MPa)

Yield Strength,Rp 0.2(MPa)

Impact,Kv/Ku(J)

Elongation,A(%)

Reduction of area,(%)

Hardness

Product shapes we supply:

- Tool Die Steels in the A-2 Tool Die Steels grade

- Stainless Steels - Special Steels in the A-2 Tool Die Steels grade

- Square and Flat Steel in the A-2 Tool Die Steels grade

- Coil Sheet in the A-2 Tool Die Steels grade

- Bar and Hollow Bar in the A-2 Tool Die Steels grade

- Forgings in the A-2 Tool Die Steels grade

- Superalloy in the A-2 Tool Die Steels grade

- Tube Pipe in the A-2 Tool Die Steels grade

- Non-Magnetic Steel in the A-2 Tool Die Steels grade

- Steels of Blade for Steam Turbine in the A-2 Tool Die Steels grade

Cross Reference, Equivalent, Similar of A-2 Tool Die Steels grade:

A-2Conditions & Properties

- +A Soft annealed

- +AC Annealed to achieve spheroidization of the carbides

- +QT Quenched and tempered

- +WW Warm worked

- +N Normalized

- +NT Normalized and tempered

- +AT Solution annealed

- +C Cold drawn / Hard

- +CR Cold rolled

- +PE Peeled

- +T Tempered